Only photon detectors can be used for measuring fast processes and moving objects

We continue detailing the snap-shot method among detector readout procedures, then move on to detector cooling technologies used for photon detectors.

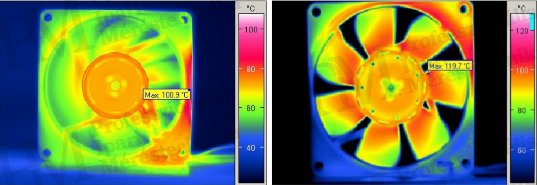

When reading detectors, the problem related to sensing moving or rotating objects can be solved with snap-shot technology. However, its application only makes sense with sufficiently fast (e.g., 10 µs integration time) photon detectors. Compared to them, thermal sensors (e.g., microbolometers) which are slower by several orders of magnitude would blur the imaging of moving objects due to the long integration time.

Details of Snap-Shot Technology

Photon detectors with snap-shot capability perform measurements (signal integration) simultaneously on each pixel, then the values measured on the pixels are "frozen" at the same time. Subsequently, as we did with serial readout, the values are read out and A/D converted line by line. Therefore, we do not use thousands of readout-digitizing circuits here, only as many as needed for reading out each row. Nevertheless, we do not distort the imaging of moving objects because all signals measured by individual detectors come from the same moment in time. From a measurement technology perspective, we can talk about a simultaneous sampling system here.

With the latest thermal cameras equipped with Snap-Shot technology, up to 850 thermal images, each 320×256 pixels, can be captured per second. However, the time required for line-by-line readout can be comparable to or even exceed the integration time of photon detectors. Therefore, the maximum image readout frequency is mainly limited by the readout. To overcome this limitation and achieve even faster image capture, we can use so-called subframes, which unfortunately result in displaying fewer details due to fewer pixels. Special thermal cameras equipped with this image processing technology can capture up to 4500 images per second at a resolution of 160×128 pixels. (Note that the detector still performs signal integration and value freezing simultaneously on all pixels. We simply limit the readout and digitization to the selected area.)

|

| Figure 1: Examples of SubFrame solutions in "Snap-Shot" technology [source: PIM] |

|

| Figure 2: Fan thermal image - left: microbolometer with serial readout, right: photon detector with "Snap-Shot" method [source: InfraTec] |

Detector Cooling Technologies for Photon Detectors

Currently, a wide variety of uncooled thermal detectors (e.g., microbolometers) are available. The most accurate and fastest measurement capabilities, as well as short- and mid-wave thermal cameras, can only be made with photon detectors - and these require cooling. Instead of liquid nitrogen solutions, high-reliability miniature cooling compressors (Stirling coolers) have become more common for ensuring their cooling. For some detector types, an additional option is the use of thermoelectric (Peltier) cooling, although this does not achieve such low temperatures, thus narrowing the range of detector designs and materials.

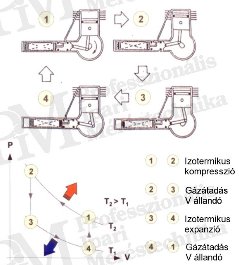

Stirling Cooling

It is based on utilizing the Carnot thermal cycle, where a gas (helium) is compressed, causing the gas to heat up, then it cools down by releasing heat to the environment. During the subsequent expansion (in another cylinder), the gas cools to a very low temperature, enabling it to absorb heat energy from the environment (in our case, from the detector). The steps proceed as a closed cycle.

In thermal cameras, a two-piston micro-compressor used for this purpose allows the cameras to be used in any position, ensuring the operation of detectors and providing measurement reliability and accuracy over a wide operating temperature range (with fairly good efficiency). However, these cooling compressors have a significant size and weight, making it impossible to create lightweight and compact thermal cameras with this technology. A more significant problem (especially for continuous applications) is that Stirling coolers form a mechanical system with limited lifespan. However, in the case of the most modern devices, this limit can approach 8000 - recently 12,000 - operating hours, maintenance-free.

|

| Figure 3: Stirling cooler principle and an actual Stirling cooler [source: InfraTec] |

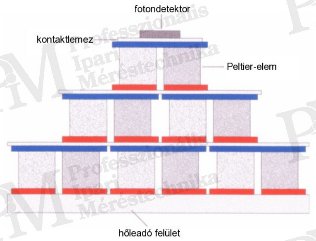

Peltier Element Cooling Also known as thermoelectric cooling, it is usually implemented in the form of a three-stage Peltier element cascade due to the low temperatures to be achieved. Its advantage over Stirling cooling is that it has no mechanical (moving and thus wearing) parts, so there is practically no limit to its lifespan. However, in return for higher energy consumption, it can only achieve less low temperatures (approximately -150 °C), which may not be sufficient for the operation of all types of photon detectors.

|

| Figure 4: Conceptual structure of 3-stage Peltier cooling / MCT-Sprite photon detector with Peltier cooling [source: InfraTec] |

Pixel resolution of matrix thermal cameras

In addition to the geometric resolution (i.e., the size of a surface "pixel" corresponding to a unique sensor in the sensor matrix), the image quality achievable with a thermal camera, or more precisely the detail of the measurement, is determined by the number of pixels in the thermal camera. The reason for this is that for graphic (visual) recognition, a certain minimum number of pixels must fall on different parts of the object being measured – just as we are accustomed to in digital photography. It is easy to understand that with more pixels, we can represent the object surface with greater detail, or the same level of detail over a larger object surface in a single thermal image. If the number of pixels is low, many images need to be taken, and for the evaluation of continuous objects and the preparation of reports, it often becomes necessary to montage the images, which is a very time-consuming task.

| |

| Figure 5: Low-cost thermal camera with 160x120 pixels (left), professional thermal camera with 1024x768 pixels (right) [source: PIM] |

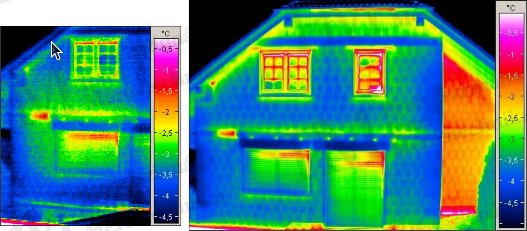

For thermal cameras, this question is not insignificant. While with digital cameras we talk about resolutions of 10, 12, or even more than 20 megapixels (20 million pixels), in the case of matrix thermal cameras, the number of pixels is typically 320×240 (thus 76,800), or 384×288, and in the case of the most professional thermal cameras, 640×480 (thus 307,200) or even 1024×768 (thus 786,432) pixels. There are also cameras with lower capabilities – common types are those working with only 160×120 pixels (thus only 19,200) or even as low as 80×80 or 96×96 pixels, which consequently can only display smaller surfaces with acceptable detail, thus strongly limiting their area of application (or even rendering the thermal camera unusable). Thanks to the development of thermal camera sensors, more and more cameras with higher pixel counts are being produced. Interestingly, the price per pixel of the most professional thermal cameras – equipped with 640×480 or 1024×768 pixel sensor matrices, with frame rates of 50 or even 240 Hz – is the most favorable (even an order of magnitude more favorable than that of low-cost cameras with fewer pixels).

|

| Figure 6: 120 x 160 and 640 x 480 pixel thermal image [source: InfraTec] |

Figure 6 vividly demonstrates the impact of the number of pixels on work efficiency: the image on the right (640×480 pixels) was taken with a single on-site button press and – as it contains all the information of the inspected building side – can also be easily inserted into the report with just a single mouse click. In contrast, the thermal image on the left (160×120 pixels) can only capture a smaller part of the building side, leaving much to be desired in terms of detail. To achieve the quality of the image on the right, 16 times as many images would be needed, and for the post-capture montage of thermal images, overlapping is also required, thus requiring many more, even 20-25 on-site image captures. Of course, well below the time required for capturing a 640×480 pixel thermal image.

The real inconvenience, however, awaits us during report writing, as we face the time-consuming task of montaging 20-25 thermal images, which depending on our experience can vary between 30 minutes and several hours. It is worth considering whether to opt for a thermal camera with fewer pixels alongside a smaller investment (and then pay for our thriftiness with multiple additional work), or to acquire a thermal camera with a higher pixel count to obtain the tool necessary for efficient work. (To be continued in our next issue.)

Rahne Eric (PIM Ltd.) pim-kft.hu, gepszakerto.hu

The content of this publication is protected by copyright, and its (even partial) use, electronic or printed re-publication, is only permitted with the indication of the source and the author's name, as well as with the author's prior written permission. Violation of copyright (Copyright) will result in legal consequences.

Copyright © PIM Professzionális Ipari Méréstechnika Kft.

1997-2025 | Minden jog fenntartva